Aikolon received an award from the City of Oulu

Aikolon, a member of the PrintoCent industry cluster, received an award from the City of Oulu for significant new international market openings.

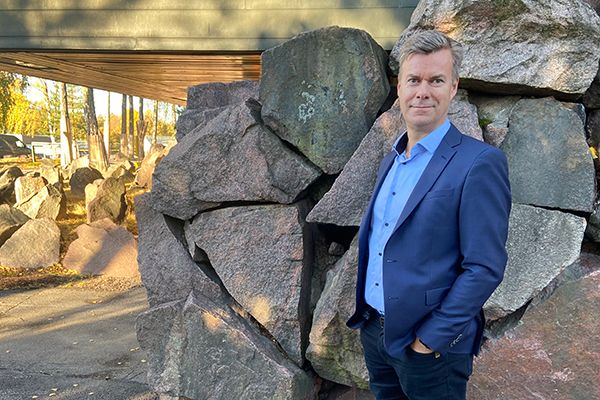

“Thank you to the City of Oulu and BusinessOulu for selecting us as the award recipient. I was surprised when I heard that Aikolon would have the honor of receiving the Export Company of the Year award. At the same time, I felt proud that in 2019, we dared to take a bold step and invest 10 million euros in a new production facility, which represents unique technology on a global scale. The production facility in Oulu manufactures high-quality and clear Aikon products, which are variously processed polycarbonate and acrylic sheets.” Says CEO Martti Hahtonen

Legal Change and Adoption of New Technology

The construction of the production facility was preceded by a legislative change that required, among other things, that the work-facing windows of forestry machine cabins be so-called bulletproof for safety reasons. This is because fragments from a broken saw chain must not penetrate the cabin windows. This requirement led to a new manufacturing technique involving the lamination of layers of lightweight and extremely impact-resistant polycarbonate plastic. Since polycarbonate scratches easily, the laminated products required a hard coating. A coating line was needed, costing 10 million euros, which also included an automatic screen-printing line, as well as lamination and thermoforming capacity. The decision to invest in a new production facility has proven to be the right one despite the challenging global situation, as demand is growing exponentially.

Printed intelligence is laminated onto products

Aikolon´s production line is highly complex, using coating chemicals, screen printing inks, and adhesive films. The material is baked, modified, and painted, and all these chemicals must work seamlessly together. Additionally, various smart technologies, such as transparent dashboards and electronic dimming films, can be laminated onto the lightweight, durable, and clear Aikon products. Aikolon is now making great strides towards a new era of technology. Previously, they were a company processing so-called "dumb" plastics, but today they are adding intelligence and new features to plastics in many different ways.

Growth in International Sales and Marketing

Aikolon has been building sales and marketing for international markets for two years, focusing particularly on Italy. The Nordic countries, Turkey, and Central Europe have also been key target markets. Despite limited resources they have introduced the Aikon® brand in desired markets and found several customers interested in technology and products. Aikon® products have gained a lot of international attention and interest in a short time, even as far as Japan.

Future Goals

Aikolon has risen in two years to the level of its German competitor, which has been making laminated and coated plastic glasses for 40 years. However, they will keep a cool head and carefully consider which projects are worth pursuing. The direction is clear. For a small Finnish family business, a realistic goal is to grow into a company with a turnover of approximately 50 million euros in ten years.